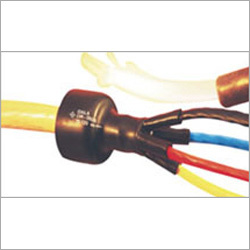

heat shrink boot

heat shrink boot Specification

- Thermal Conductivity

- Low

- Installation Guideline

- Slide over wire/cable and apply heat for shrinking

- Size

- Standard sizes available for cable diameters

- Density

- Gram per cubic centimeter(g/cm3)

- Feature

- Heat Shrinkable Durable Resistant to Environmental Factors

- Surface Treatment

- Smooth Surface

- Layer

- Single Layer

- Coating Type

- Non-Conductive Coating

- Product Type

- Heat Shrink Boot

- Material

- Polyolefin

- Rated Voltage

- Up to 15kV

- Tensile Strength

- High

- Width

- Customizable based on cable size

- Thickness

- Standard Thickness for cable boots

- Application

- Wire and Cable Protection

- Breakdown Voltage

- High Voltage Strength

- Heat Conductivity

- Low

- Color

- Black

- Max Withstanding Temperature

- 125C

About heat shrink boot

Heat Shrink Boots are manufactured from high quality cross-linked Polyolefin material conforming to stringent military specifications.This boots provides an exceptional insulation, strain-relief & long term service reliability in connector joints of cable harness.

Features / Benefits:

- Excellent Electrical strength & Mechanical toughness

- Excellent resistance to weathering, UV rays, Chemicals, Oils, Fuels & Solvents

- Flame retardant & Self extinguishing

- High shrink ratio, shrink temperature 120 C

- Easy to install even on connector, already mounted to cable

- Not melting and resistant to cold flow

- Wide operating temperature range

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Shrinkable Moulded Shapes Category

Anti-Tracking Breakout

Material : Crosslinked polyolefin

Installation Guideline : Ensure clean and dry surface before installation

Size : Customizable

Product Type : Breakout boots

Surface Treatment : None

Application : Cable termination protection

Right Angle -Straight

Material : Silicone rubber

Installation Guideline : Follow safety standards for electrical installations

Size : Standard sizes for cable compatibility

Product Type : Insulation sleeves

Surface Treatment : Smooth and polished finish

Application : Cable terminations and connections

Low Voltage Breakout

Material : Polymeric material

Installation Guideline : Apply over cable joints ensure a tight fit

Size : Customizable size based on cable thickness

Product Type : Breakout

Surface Treatment : Smooth finish

Application : Electrical cable management

Cable End Caps

Material : Polyolefin or similar polymer

Installation Guideline : Slide onto cable and heatshrink for secure fitting

Size : Various sizes available

Product Type : Cable End Caps

Surface Treatment : Smooth finish

Application : Electrical insulation and cable sealing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS