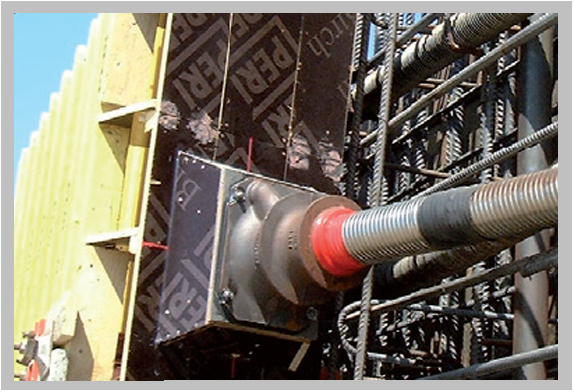

Heat Shrink Sleeve for Post Tensioning Duct Joint

About Heat Shrink Sleeve for Post Tensioning Duct Joint

Heat Shrink Coupler is a Tubing used for jointing the posttensioning ducts to ensure leak tightness of connections between two consecutive portion of duct.

These tubes are manufactured from high quality Cross-linked Polyolefin material. Hot melt adhesive lining provides 100% sealing according to IP 68 (Ingress Protection). Heat Shrink Couplers ensure a tight seal around the pre-stressing duct connections.

FEATURES & BENEFITS :-

- Easy & Quick Installation. No special skill required.

- High resistance to Impact & Abrasion.

- Suitable for Wet and Dry underground conditions.

- Joint in-line with pipe.

- Superior elastomeric characteristics allows better conformance over irregular contours.

- High Shrink ratio (3:1) helps to reduce the stock requirements with few sizes covering greater pipe application range.

- Resistant to Heat, UV rays, Vibration, Sand-blasting & Harsh Industrial conditions.

- Customized dimensions, length & colour available.

Technical Specification

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 20 Mpa (N/mm 2) (min.)

- ASTM D638

- Ultimate Elongation

- 350 % (min)

- ASTM D638

- Longitudinal Change

- -10% (max.)

- ASTM D2671

- Hardness

- 45 ±10 Shore D

- ASTM D2240

- Water absorption

- 0.5 % (max.)

- ASTM D570

- Thermal

- Accelerated ageing

- (1200C for 500 hrs)

- ASTM D2671

- Tensile Strength

- 14 Mpa (N/mm2 ) (min.)

- ASTM D638

- Ultimate Elongation

- 300 % (min.)

- ASTM D638

- Low Temperature Flexibility

(-40 C for 4 hrs.) - No Cracking

- ASTM D2671

- Heat Shock

(250 C for 30 min.) - No cracking or flowing

- ESI 09-11

- Shrink Temperature

- 1250C

- IEC 216

- Continuous Temperature Limit

- -40 to +1100C

- IEC 216

- Electrical

- Dielectric Strength

- 12 KV/mm.(min)

- ASTM D149

- Volume Resistivity

- 1 x 1014 Ohm.cm (min)

- ASTM D257

- Dielectric constant

- 5 (max.)

- ASTM D150

Selection Chart

- Code

- D min

(mm) - d max

(mm) - T±10%

(mm) - Length/Pc.

(mm)

- GCMW 70/22

- 70

- 22

- 2.7

- 300

- GCMW 90/28

- 90

- 28

- 3.0

- 300

- GCMW 105/30

- 105

- 30

- 3.0

- 300

- GCMW 115/34

- 115

- 34

- 3.2

- 300

- GCMW 130/36

- 130

- 36

- 3.2

- 300

- GCMW 140/42

- 140

- 42

- 3.2

- 300

- GCMW 160/50

- 160

- 50

- 3.3

- 300

- GCMW 180/55

- 180

- 55

- 3.3

- 300

- GCMW 200/60

- 200

- 60

- 3.5

- 300

- GCMW 250/70

- 250

- 70

- 3.5

- 300

- GCMW 320/90

- 320

- 90

- 3.5

- 300

- GCMW 375/110

- 375

- 110

- 3.5

- 300

- GCMW 425/125

- 425

- 125

- 3.5

- 300

- GCMW 550/157

- 550

- 157

- 3.5

- 300

- GCMW 680/200

- 680

- 200

- 3.5

- 300

- GCMW 760/215

- 760

- 215

- 3.5

- 300

- GCMW 863/250

- 863

- 250

- 3.5

- 300

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in New Item Category

Screened Separable Connector

Application : Electrical and power transmission systems, Other

Product Type : Screened Separable Connector

Heat Shrinkable Termination

Application : Other, Electrical Termination

Product Type : Heat Shrinkable Termination

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS