Cable Repair Products

Cable Repair Products Specification

- Insulation

- High insulation, self-extinguishing

- Usage & Applications

- Restoring insulation integrity, preventing moisture ingress, covering cable joints

- Features

- Easy to install, High durability, Water-resistant, Flame-retardant, Flexible design, UV resistant

- Impedance

- Not applicable (for repair - not new cable)

- Diameter

- Standard sizes: 10mm, 20mm, 35mm, 50mm, 70mm, 100mm

- Rated Temperature

- -40C to +125C

- Tensile Strength

- 10.4 MPa

- Dielectiric Strength

- >15kV/mm (depends on repair product grade)

- Cable Type

- Suitable for LV/MV single core and multicore cables

- Locking Type

- Wrap and heat activated

- Operating Temperature

- -30C to +110C

- Weight

- Approx. 80g to 150g per meter (depends on diameter)

- Armored Material

- Not applicable or as per cable design

- Install Type

- Cold or heat shrink (flame or hot air gun), wrap-around

- Product Type

- Cable Repair Sleeve/Heat Shrink Tubing

- Length

- Varies as per requirement (standard: 1 meter, 2 meter, 5 meter, or custom)

- Voltage

- Up to 1000V AC / 1500V DC

- Insulation Material

- Polyvinyl Chloride (PVC), Cross-linked Polyethylene (XLPE), Heat Shrink Polyolefin

- Application

- Cable Insulation, Repairing damaged cables, Outdoor installations, Power and telecommunication cables

- Conductor Material

- Not applicable (used for outer cable repair, not conductor)

- Jacket Material

- Polyolefin, PVC

- Storage Temperature

- -10C to +50C

- Connector Color

- Black (standard), Red, Blue, Yellow, Green (optional)

- Shield Material

- None/Optional Aluminum Foil for Shielded Variants

- Jacket Color

- Black (default), Red, Yellow, Blue (optional)

- Dimension (L*W*H)

- Variable; typically 1000mm x 20mm x 2mm (custom sizes available)

- Color

- Black, Red, Blue, Yellow, Green

- Material

- Heat Shrink Polyolefin, PVC

- Size

- Various sizes: diameter from 10mm to 100mm

- Temperature Resistance

- Stable performance from -40C to +125C

- UV Resistance

- Yes

- Package Type

- Individually packed or in bulk rolls/sleeves

- Sealing Type

- Waterproof and environmental sealing

- Adhesive Type

- Hot melt (integral adhesive lining for waterproof sealing)

- Liner

- Optional adhesive lining

- Flame Retardant

- Yes

- RoHS Compliance

- Yes

- Typical Repair Application

- Quick field repair or emergency cable restoration

- Environmental Resistance

- Resistant to chemicals, oils, fungus, and UV

- Repair Method

- Heat shrink, wrap-around, spiral or patch style

- Recommended Tools

- Hot air gun, scissors/cutter

- Shrink Ratio

- 3:1 or 4:1 (depending on size/type)

- Flexibility

- Excellent for use on bent or irregular cable surfaces

- Minimum Shrink Temperature

- 120C

- Maximum Continuous Voltage Withstand

- Up to 1000V

- Shelf Life

- Up to 36 months if stored as recommended

About Cable Repair Products

Cable Repair Products

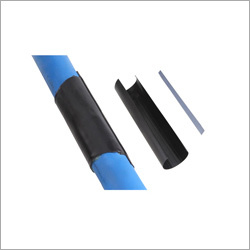

Heat Shrink Wrap Around Sleeve - INSULSLEEVE

Heat Shrink Wrap Around Sleeve is a cross linked polyolefin 'tube' which is folded around the cable/pipe, zipped up with a stainless steel channel and then heat shrunk.It is also cold as (Cable Repair Sleeve).

Shut down of system not required for repair.

- Shut down of system not required for repair.

- Hotmelt adhesive provides complete environmental sealing and insulation.

- High resistance to UV rays, chemicals, corrosion, fungus, etc.

- Temperature sensitive paint changes colour when heat shrinking process is complete.

- Maximum length available upto 1500 mm.

- Meets IP 68 (Ingress Protection)

Recommended Thickness :

All dimensions in mm

- Part number /size

- Diameter (D)

- Thickness ( 20 %)

- Application

- Supplied

- Recovered

- (recovered)

- Cable Range

- GWS-55/8

- 55

- 8

- 2.7

- 42-8

- GWS-76/18

- 76

- 18

- 2.7

- 62-22

- GWS-105/28

- 105

- 28

- 2.7

- 92-30

- GWS-140/35

- 140

- 35

- 2.7

- 122-38

- GWS-190/46

- 190

- 46

- 2.7

- 160-50

- GWS-240/50

- 240

- 50

- 2.7

- 200-55

Length as per requirement (maximum 1500 mm)

-

For Cable Repairs

-

For the protection of Cable joint

-

For corrosion protection of Oil, Water & Gas pipeline

TECHNICAL SPECIFICATION

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 17 N/mm2 (MPA)(min)

- ASTM D638

- Ultimate Elongation

- 300% (Min.)

- ASTM D638

- Longitudinal Change

- -10% (max.)

- ASTM D2671

- Water Absorption

- 0.2 % (max.)

- ASTM D570

- ESCR 48 hrs. for 50oC

- No Crack

- ASTM D570

- Torchability

- No split

- Te 201 AOL

- Thermal

- Accelerated Ageing

- (120oC for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 15 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 220 % (Min.)

- ASTM D 638

- Temperature indicating Paint Conversation

150oC for 30 min

250oC for 5 min -

No Change

Colour Cahnge -

Visual

Visual

- Electrical

- Dielectric Strength

- 12 KV/mm. (Min.)

- ASTM D149

- Chemical

- Chemical resistance in 0.1 N sol.

of

Na2 , So4,Na2,Nacl2,H2so4

Tensile Strength

Elongation

15 N/mm2 (MPA) (min)

200 % (min)- ASTM D2671

ASTM D638

ASTM D638

Versatile, Reliable Insulation Restoration

These cable repair products are purpose-built for quick field repairs or emergency cable restoration. Their robust composition ensures high dielectric strength, excellent tensile strength, and strong resistance to chemicals, oils, fungus, and UV exposure. The flexible material conforms to irregular surfaces, making it ideal for restoring insulation integrity, preventing moisture ingress, and securing cable joints in both indoor and outdoor environments.

Easy, Efficient Installation for All Applications

Installation is simple: wrap or slide the heat shrink product over the damaged area, then apply heat with a hot air gun until the product conforms and seals. Optional adhesive lining ensures waterproof, airtight protection. Products are available in individually packed sleeves or bulk rolls, in various colors and sizes to suit LV/MV single and multicore cable repairs. Shelf life is up to 36 months under recommended storage.

FAQs of Cable Repair Products:

Q: How do I use heat shrink cable repair products for damaged cables?

A: To use these products, first clean and prepare the damaged cable area. Place the heat shrink sleeve, wrap, or spiral over the section. Then, using a hot air gun, apply heat evenly until the material shrinks to fit snugly. The integral hot melt adhesive lining activates to create a waterproof and environmentally sealed repair.Q: What types and sizes are available for different cable repairs?

A: Cable repair products are available in various shrink ratios (3:1 or 4:1), diameters (10mm to 100mm), lengths (1m, 2m, 5m, or custom), and colors (black, red, blue, yellow, green). Wrap-around, spiral, and patch variants cater to single core, multicore LV/MV cables, and irregular cable surfaces.Q: When should I use heat shrink repair products instead of replacing the entire cable?

A: These products are best used for quick field repairs, emergency restorations, or when replacing the entire cable would be time-consuming or costly. They are designed to restore insulation integrity, prevent further damage, and provide waterproof and UV-stable protection in both outdoor and indoor applications.Q: Where can these products be applied, and are they suitable for outdoor use?

A: Heat shrink repair sleeves and wraps are suitable for power and telecommunication cables, including those installed outdoors. Their robust construction provides resistance to chemicals, oils, fungus, and UV exposure, making them ideal for harsh environments and outdoor installations.Q: What tools are recommended for effective installation?

A: A hot air gun is the most recommended tool for shrinking and activating the adhesive lining. Scissors or a cutter can be used to trim the product to the required length prior to installation. No special chemicals or equipment are required beyond standard safety gear.Q: What are the main benefits of using these cable repair products?

A: Benefits include high insulating capability, excellent flexibility for irregular cables, quick installation, strong environmental and water resistance, flame-retardant properties, and long-term durability. They also offer RoHS compliance and can be stored for up to 36 months if kept at recommended conditions.Q: What should be considered for storage and shelf life of these products?

A: Store the products at temperatures between -10C and +50C in a dry, cool environment. When stored as recommended, they maintain a shelf life of up to 36 months without degradation of performance or reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Sealing & Repair Products Category

End Cap with Cable Pulling Eye

Product Type : End Cap with Cable Pulling Eye

Insulation : Highgrade insulation

Jacket Material : Other, Highstrength plastic

Usage & Applications : Pulling and terminating power cables in industrial, commercial, or utility installations

Jacket Color : Black

Insulation Material : Other, EPDM Rubber

Temper Proof End Seal

Product Type : Temper Proof End Seal

Insulation : High grade insulation

Jacket Material : Other, PVC/Polymer

Usage & Applications : Cable termination, End sealing, Safety

Jacket Color : Black

Insulation Material : Other, PVC/Polymer

Wrap Around Sleeve

Product Type : Wrap Around Sleeve

Insulation : Yes, electrical insulation provided

Jacket Material : Other, Polyolefin

Usage & Applications : Repairing of cable jackets, Insulation restoration, Environmental protection

Jacket Color : Black

Insulation Material : Other, Polyolefin or modified polyethylene

Cable Repair Sleeve

Product Type : Cable Repair Sleeve

Insulation : Double insulation walls

Jacket Material : Other, Crosslinked Polyolefin

Usage & Applications : Outdoor/indoor cable repair, electrical insulation, waterproof cable jointing

Jacket Color : Black

Insulation Material : Other, Polyolefin Heat Shrinkable Material

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS