Wrap Around Sleeve

About Wrap Around Sleeve

Provided Wrap Around Sleeve is designed to quickly repair damaged cable jacketing. These sleeves can be used as insulation material on cable and splices up to 1000 volts and as jacket repair material on cable up to 35kV. Further, offered sleeves are widely used as a wrapping or covering sheet for isolation of the heat operational medium from device or pipeline, demanded in diverse industries such as oil, chemical, refinery and so on. Our offered sleeves are known for their features like proper leak proof coating, excellent durability, longer working life, heat shrink. Apart from this, our offered Wrap Around Sleeve consists of a radiation cross-linked heat shrinkable backing, coated on the inside with a proprietary formulation of heat activated adhesive or mastic.

Cable Repair Products

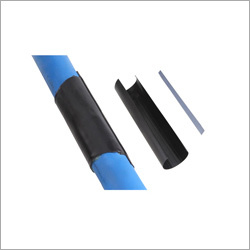

Heat Shrink Wrap Around Sleeve - INSULSLEEVE

Heat Shrink Wrap Around Sleeve is a cross linked polyolefin 'tube' which is folded around the cable/pipe, zipped up with a stainless steel channel and then heat shrunk.It is also cold as (Cable Repair Sleeve).

Shut down of system not required for repair.

- Shut down of system not required for repair.

- Hotmelt adhesive provides complete environmental sealing and insulation.

- High resistance to UV rays, chemicals, corrosion, fungus, etc.

- Temperature sensitive paint changes colour when heat shrinking process is complete.

- Maximum length available upto 1500 mm.

- Meets IP 68 (Ingress Protection)

Recommended Thickness :

All dimensions in mm

- Part number /size

- Diameter (D)

- Thickness (± 20 %)

- Application

- Supplied

- Recovered

- (recovered)

- Cable Range

- GWS-55/8

- 55

- 8

- 2.7

- 42-8

- GWS-76/18

- 76

- 18

- 2.7

- 62-22

- GWS-105/28

- 105

- 28

- 2.7

- 92-30

- GWS-140/35

- 140

- 35

- 2.7

- 122-38

- GWS-190/46

- 190

- 46

- 2.7

- 160-50

- GWS-240/50

- 240

- 50

- 2.7

- 200-55

Length as per requirement (maximum 1500 mm)

-

For Cable Repairs

-

For the protection of Cable joint

-

For corrosion protection of Oil, Water & Gas pipeline

TECHNICAL SPECIFICATION

- PROPERTIES

- VALUE

- STANDARD

- Physical

- Tensile Strength

- 17 N/mm2 (MPA)(min)

- ASTM D638

- Ultimate Elongation

- 300% (Min.)

- ASTM D638

- Longitudinal Change

- -10% (max.)

- ASTM D2671

- Water Absorption

- 0.2 % (max.)

- ASTM D570

- ESCR 48 hrs. for 50oC

- No Crack

- ASTM D570

- Torchability

- No split

- Te 201 AOL

- Thermal

- Accelerated Ageing

- (120oC for 500 Hrs)

- ASTM D2671

- Tensile Strength

- 15 N/mm2 (Mpa) (min.)

- ASTM D 638

- Ultimate Elongation

- 220 % (Min.)

- ASTM D 638

- Temperature indicating Paint Conversation

150oC for 30 min

250oC for 5 min -

No Change

Colour Cahnge -

Visual

Visual

- Electrical

- Dielectric Strength

- 12 KV/mm. (Min.)

- ASTM D149

- Chemical

- Chemical resistance in 0.1 N sol.

of

Na2 , So4,Na2,Nacl2,H2so4

Tensile Strength

Elongation

15 N/mm2 (MPA) (min)

200 % (min)- ASTM D2671

ASTM D638

ASTM D638

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS