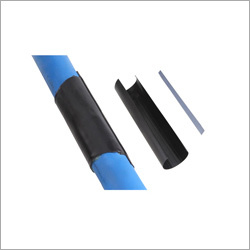

Cable Repair Sleeve

Cable Repair Sleeve Specification

- Locking Type

- Adhesive lined inner wall for sealing

- Cable Type

- Suitable for LV & MV, XLPE, PVC, and PILC cables

- Weight

- Approx. 80150 g (depending on size)

- Features

- Easy to install, Weatherproof, Corrosion resistant, High durability, UV resistant, Water-tight seal

- Usage & Applications

- Outdoor/indoor cable repair, electrical insulation, waterproof cable jointing

- Insulation

- Double insulation walls

- Dielectiric Strength

- 15 kV/mm

- Tensile Strength

- >14 MPa

- Diameter

- Available for cables from 10mm to 50mm

- Rated Temperature

- -40C to +105C

- Install Type

- Heat shrink installation requires a heating gun or torch

- Operating Temperature

- -40C to +105C

- Product Type

- Cable Repair Sleeve

- Length

- Customizable as per application (typically 0.5 to 1.5 meter)

- Voltage

- Up to 1 kV

- Insulation Material

- Polyolefin Heat Shrinkable Material

- Application

- Repair and insulation of damaged cables, outdoor and indoor cable protection

- Jacket Material

- Cross-linked Polyolefin

- Storage Temperature

- -20C to +50C

- Jacket Color

- Black

- Dimension (L*W*H)

- Depends on cable size; standard: 500mm x 40mm x 2mm

- Material

- Heat Shrink Polyolefin

- Color

- Black

- Size

- Available for various cable diameters: 10mm 50mm

- Shrink Ratio

- 3:1 or 4:1 (Depending on sleeve variant)

- Halogen Free

- Yes

- Custom Sizes Available

- Yes

- Compliance Standards

- IEC 60684, RoHS compliant

- Flame Retardant

- Yes

- Packaging Type

- Individual polybag or bulk as per order

- Minimum Shrink Temperature

- 120C

- Lead Time

- 2-7 working days after order confirmation

- Inner Adhesive Layer

- Hot melt adhesive ensures waterproof sealing

- Waterproof Standard

- IP68 after proper installation

- Elongation at Break

- >350%

- Shelf Life

- Over 24 months in standard storage conditions

- Environmental Resistance

- Weather, chemical, and abrasion resistant

- UV Resistance

- Excellent

About Cable Repair Sleeve

Heat Shrink Cable Repair Sleeves is manufactured from High Quality Cross-linked polyolefin material. Heat Shrink Cable Repairing Sleeve is an adhesive lined, wraparound heat shrink that can be easily applied without the need for disconnection. It provides superior environmental sealing, rugged mechanical protection and high performance electrical insulation.

Features & Benefits:

- Provides permanent waterproof barrier & environmental seal.

- Shrink ratio 3:1.

- Chemical, copper corrosion and fungus resistance.

- Shut down of system not required for repair.

- Hotmelt adhesive provides complete environmental sealing and insulation according to IP 68 (Ingress Protection).

- High resistance to UV rays, chemicals, corrosion, fungus, etc.

- Significant protection advantages over insulating tape.

- Reduces total labour and installation cost.

- Stocking only a few sizes will fit most repair needs.

- Sleeve can be cut to size in field to suit application.

- Custom dimensions available on request.

- Can also be offered in optional Medium (GMRS) and Heavy (GHRS) wall versions.

Selection Chart

- Gala Code

- Cable OD

- Length

- Overlap Length

- (mm)

- (mm)

- (mm)

- GMRS-64

- 5 - 10

- 100/200/300

- 25

- GMRS-90

- 8 - 16

- 100/200/300

- 25

- GMRS-132

- 12 - 28

- 100/200/300

- 25

- GMRS-235

- 24 - 55

- 100/200/300

- 25

- GMRS-361

- 40 - 85

- 100/200/300

- 25

- GMRS-502

- 55 - 122

- 300/400

- 25

Applications:

- Repair of damaged cable jackets.

- Retrofit protection of connections.

- Connectorized cable repair.

- Used in confined spaces underground and ideal for protections of defrayed cable / connectors.

- Cable / conduit transitions.

- Cable / wire / rope bundles.

- Used in communication, Electrical, Utility, Industrial, Shipboard, Offshore, Marine, Wire and Cable industries.

TECHNICAL SPECIFICATION

- Properties

- Value

- Standard

- Physical

- Tensile Strength

- ASTM-D-638

- 12 N/mm2 (Min.)

- Elongation

- ASTM-D-638

- 300% (Min.)

- Water Absorption

- ASTM-D-570

- 0.15 (Max)

- Low Temp. Flexibility

- ASTM-D-2671

- -55 C

- Specific Gravity

- ASTM-D-792

- 1.4

- Longitudinal Change

- ASTM-D-638

- -10%(Max)

- Flammability

- ASTM-D-2671

- Pass

- Thermal

- Operating Temp.

- IEC216

- -55 C to +125 C (Outer Wall)

- Heat Shock

- No dripping, cracking or flowing

- @ 250 C 4 hrs

- (Outer Wall)

- Chemical:

- Fungus Resistance

- MIL-1-7444

- Inert

- Copper Corrosion

- ASTM-D-2671 B

- Good

- Copper Corrosion

- ASTM-D-2671 B

- Good

- Electrical

- Dielectric Strength

- ASTM-D-2671

- >15kV / mm

- Dielectric Constant

- ASTM-D-150

- 3.0(Max.)

- Volume Resistance

- ASTM-D-257

- 10 Ohm / cm (Min)

Superior Cable Protection and Repair

Engineered for maximum durability, the Cable Repair Sleeve offers robust shielding against moisture, UV, chemicals, and abrasion. Its secure 3:1 or 4:1 shrink ratio ensures a tight fit, restoring the integrity of cables in various environments. The flame retardant, halogen-free polyolefin jacket meets international safety standards, making it suitable for a broad spectrum of electrical and environmental conditions.

Waterproof and Weatherproof Sealing

With an inner hot melt adhesive layer, the sleeve delivers a reliable IP68 waterproof seal after proper installation. It resists harsh outdoor elements, extending cable lifespan in challenging weather. Whether used for maintenance or emergency repairs, its water-tight barrier prevents corrosion and electrical fault risks, making it indispensable for cable protection.

Customizable for Diverse Applications

Lengths, diameters, and packaging can be tailored to diverse needs, with sleeves available for cables from 10mm to 50mm. Suitable for PVC, XLPE, and PILC cables in LV and MV classes, its perfect for utilities, industrial settings, and outdoor installations. Fast lead times and varied packaging options support large or small-scale requirements.

FAQs of Cable Repair Sleeve:

Q: How do I properly install the Cable Repair Sleeve for the best waterproofing performance?

A: To ensure an IP68-rated waterproof seal, clean and prepare the damaged cable area, position the sleeve over the section, and heat it evenly using a heat gun or torch. The inner hot melt adhesive melts and flows, sealing the sleeve tightly around the cable. Allow it to cool before handling. Proper installation is crucial for optimal performance.Q: What are the main benefits of using a heat shrinkable Cable Repair Sleeve compared to traditional repair methods?

A: The sleeve provides double insulation, fast and easy installation, strong mechanical protection, and a water-tight seal. Its flame retardant and halogen-free construction offer enhanced safety, while the products high elongation and UV resistance ensure long-term durability even in harsh outdoor environments.Q: When should I choose a 3:1 versus a 4:1 shrink ratio for my cable repairs?

A: Select 3:1 shrink ratio for standard cable repairs and 4:1 for cables with greater diameter differences or irregular shaping. The higher ratio is particularly useful for cables with thicker insulation or connectors, ensuring a snug fit and effective sealing.Q: Where can the Cable Repair Sleeve be used, and what cable types is it compatible with?

A: It is suitable for use both indoors and outdoors, and is compatible with a variety of cables, including LV & MV, PVC, XLPE, and PILC types, typically within the 10mm to 50mm diameter range. The product can be used by electricians, utilities, industrial maintenance teams, and others needing reliable cable protection.Q: What is the process for ordering a custom size or bulk quantity of sleeves?

A: Custom sizes and bulk orders can be placed by specifying the required cable diameter, length, and preferred packaging (individual or bulk polybags). Lead times range from 2 to 7 working days after order confirmation, making it convenient for large or urgent projects.Q: How long can the Cable Repair Sleeve be stored before use, and what are the recommended conditions?

A: The sleeve maintains its properties for over 24 months when stored in cool, dry conditions between -20C and +50C. Proper storage ensures the adhesive and shrink characteristics remain effective for future use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cable Sealing & Repair Products Category

End Cap with Cable Pulling Eye

Usage & Applications : Pulling and terminating power cables in industrial, commercial, or utility installations

Insulation : Highgrade insulation

Product Type : End Cap with Cable Pulling Eye

Storage Temperature : 20C to +60C

Connector Color : Silver

Dimension (L*W*H) : 180mm x 80mm x 80mm

Cable Repair Products

Usage & Applications : Restoring insulation integrity, preventing moisture ingress, covering cable joints

Insulation : High insulation, selfextinguishing

Product Type : Cable Repair Sleeve/Heat Shrink Tubing

Storage Temperature : 10C to +50C

Connector Color : Black (standard), Red, Blue, Yellow, Green (optional)

Dimension (L*W*H) : Variable; typically 1000mm x 20mm x 2mm (custom sizes available)

Wrap Around Sleeve

Usage & Applications : Repairing of cable jackets, Insulation restoration, Environmental protection

Insulation : Yes, electrical insulation provided

Product Type : Wrap Around Sleeve

Storage Temperature : 40C to +60C

Connector Color : Black

Dimension (L*W*H) : Custom sizes available

Temper Proof End Seal

Usage & Applications : Cable termination, End sealing, Safety

Insulation : High grade insulation

Product Type : Temper Proof End Seal

Storage Temperature : 20C to 70C

Connector Color : Black

Dimension (L*W*H) : Custom / As required

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS